When considering insulation for your home, it’s important to understand the facts about different product types and options. First things first: there is no such thing as a “best insulator.” Surprised? According to the Building Sciences Corporation (BSC), all insulation types perform equally well when properly installed and air sealed.1

Understanding different insulation materials

There are four main types of home insulation products on the market today: fiberglass insulation, mineral wool insulation, cellulose insulation, and spray foam insulation. Each of these options have different qualities and attributes that may inform your choice of materials.

See More

–+Mineral wool insulation (also called rock or slag wool insulation): Made from rock, blast furnace slag, and other raw materials which are melted and spun into fibers to resemble the texture of wool. Mineral wool comes in batts, rolls or loose-fill forms. Like fiberglass, it is also used throughout a house in sidewalls, attics, floors, crawl spaces, cathedral ceilings, and basements.

Cellulose insulation: Composed mostly of cellulose fibers usually derived from paper, paperboard stock or wood, and made with or without binders. Cellulose is chemically treated to resist fire.

Spray foam insulation: Chemical-based insulation that is mixed on-site by insulation contractors to create foam, and applied with a sprayer in attics and into wall cavities. The two main types of spray foam insulation are open cell foam insulation and closed cell foam insulation. The properties of each are somewhat different.

Value and Energy Savings

What You Should Know

–+The type of insulation material you choose has little impact on your energy savings. There are 3 things that impact the efficiency of your insulation and the return on your investment:

- Correct installation

- Proper air sealing

- Getting the most insulation R-value per dollar. R-value is simply a material’s capacity to resist heat flow. The higher the insulation R-value, the greater the insulating power. Any material of the same R-value will insulate equally well if installed and sealed correctly.2

Provides Air Sealing

What You Should Know

–+Fiberglass, mineral wool, spray foam and loose fill cellulose all require air sealing to work properly.

Spray foam provides some air sealing if applied properly. However, research shows that no insulation product is proven to provide a continuous, whole-home air barrier.3 So any type of insulation you choose will likely require air sealing.

Product Quality Control

What You Should Know

–+Fiberglass and mineral wool insulation are produced in highly sophisticated manufacturing facilities across the US with quality controls in place.

Cellulose insulation is commonly treated with chemicals to make it fire resistant, however the application process isn’t standardized, and there is evidence that the fire resistance wears off over time.4

Spray foam insulation is essentially manufactured on site, at your home, prior to application. There are many factors that may influence the quality of the resulting product.

Factors that can impact spray foam quality include:

- The mixing process of the two chemicals at your home—which is in the hands of the insulation contractor

- The age of the chemicals—which have a shelf life that can affect mixing and application

- Air temperature and humidity during installation—if the relative humidity is too high or the air temperature too low, there can be problems with installation5

- Temperature of chemical storage—optimal storage is between 65 and 85°F, depending on manufacturer guidance.6 If there are variances or chemicals are mis-stored, the product can be compromised

Installation Variables

What You Should Know

–+Installation quality can vary widely for all insulation types, but some materials are easier to assess at installation than others.

Fiberglass and mineral wool installation—takes time and attention, but quality of installation can easily be assessed visually following a few simple guidelines.

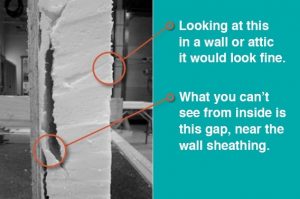

Spray foam installation—can be affected by many factors, such as ambient temperature, humidity, and cleanliness at the application site.5 It is also difficult to see gaps or voids in material on the actual application surface by looking at the top layer of foam.6

Independent third-party testing has shown significant gaps or voids where spray foam didn’t adhere to the exterior sheathing, even in controlled lab conditions —which can obviously affect product performance. These voids may only be noticeable if a cross section of the wall is cut out or thermal imaging equipment is used.

Acoustic Performance

What You Should Know

–+Insulation materials are rated by the quality of noise reduction and sound interference they achieve. There are different kinds of sound, and different means of rating acoustic performance.

Noise Reduction Coefficient (NRC):

scores materials on a scale of 0-1, higher being better

Sound Transmission Coefficient (STC):

scores materials based on the amount of noise transmission through a barrier, higher being better

Fiberglass and mineral wool insulation:

NRC: 1 7

STC: 43 8

Spray foam insulation:

NRC: .75 7

STC: 37-39 9

Cellulose insulation:

NRC: .757

Health Impacts

What You Should Know

–+When choosing an insulation material, you’ll of course want to consider any impact on your family’s health.

Fiberglass has a proven track record for safe use.10

You may see claims about the presence of formaldehyde in fiberglass and mineral wool. 90% of the residential fiberglass insulation on the market today is in fact formaldehyde free. It’s important to know that the Consumer Product Safety Commission has determined that “fibrous glass insulation and ceiling tiles would have little impact on in-home formaldehyde levels”11 The International Agency for Research on Cancer (IARC), the US National Toxicology Program (NTP) and the California Office of Environmental Health Hazard and Assessment have all stated that fiberglass and mineral wool thermal and acoustic insulations are not considered classifiable as carcinogens. You may still see claims about fiberglass being a carcinogen, but major US and global health bodies have made their views clear.12

Spray foam safety is still under evaluation. You may want to investigate further if you’re concerned about chemical impact in your home. According to the California Department of Toxic Substances Control, methylene diphenyl diisocyanate, one of the main ingredients in spray polyurethane foam insulation, has inherent health risks.

Methylene diphenyl diisocyanate is known to damage lungs, cause asthma, and trigger asthma attacks in workers who install foam. The US EPA has declared similar concerns, and more info on them can be found here.

Currently, different spray foam manufacturers offer conflicting guidance on how long a home needs to be vacated during the installation and curing process. There are no established or approved timelines from any government body.

Recycled Content

What You Should Know

–+Fiberglass insulation—contains 40-60% recycled content, depending on manufacturer and facility.

Slag wool and rock wool (the two types of mineral wool insulation)—contain 10-15% and 70-90% recycled content respectively.

Cellulose insulation —Has significant recycled content, with manufacturers often claiming 80% or more.

Spray foam insulation—Is strictly a chemical product and therefore contains very little recycled content.

Fire Safety

What You Should Know

–+Fiberglass and mineral wool insulation are naturally non-combustible.13

Spray foam insulation will ignite at 700°F.14

Cellulose insulation—Requires approximately 20%, by weight, of fire retardants to reduce flammability.15 This adds fire-resistance, though the material itself is not non-combustible or smolder-resistant and products must carry a fire hazard warning.

The Consumer Products Safety Commission requires cellulose manufacturers to warn customers that the product presents a fire hazard.16

The risks are real. In 2015, Allstate Insurance is suing an insulation contractor over a house fire allegedly caused by improper installation of cellulose insulation.

Moisture

What You Should Know

–+No insulation product alone is capable of preventing moisture-related problems in the home. Home moisture management is complex—it’s about letting moisture in, letting it out, and giving it the chance to evaporate.

Installing any insulation product, in part of or all of a home, can’t magically solve or prevent moisture problems. However, moisture is an important factor to consider when installing installation in a new or existing home.

In building a new home—ask your builder about their approach to addressing moisture. The strategy should take into consideration insulation, vapor retarders, material choices in the building envelope and your local climate.

In an existing home with moisture issues—hiring a specialist to diagnose and fix moisture problems is the prudent choice. The solution must consider the same factors as in new homes, though addressing the issues may be more difficult.

Mold

What You Should Know

–+If you’re concerned about mold in your home, it’s important to understand the facts. Mold is a product of moisture and the presence of food (any organic material) for mold spores. Any moisture issues should be addressed immediately (see above).

If products in the home are composed of organic material, they can be food for mold.

- Cellulose insulation is a possible food source if not properly treated.

- Spray foam, fiberglass and mineral wool insulation are not food sources, however mold can grow on any surface when the conditions are right.

Note: Some insulation products advertise “mold resistance,” but mold growth can occur on ANY surface if there is water and food present. No product can prevent mold.

References

–+- www.naima.org/publications/Thermal_Metrics_Project_Report.PDF

- www.naima.org/publications/Thermal_Metrics_Project_Report.PDF

- “Field Demonstration of Alternative Wall Insulation Products.” Prepared for the U.S. Environmental Protection Agency by the NAHB Research Center Inc. November 1997

- Environmental Cycling of Cellulosic Thermal Insulation and Its Influence on Fire Performance; Donald W. Belles and Associates, Inc., “Loose-Fill Cellulose Insulation – An Aging Problem,” J. Applied Fire Science, Vol. 30, 295-303, 1993-94; Mark McLees, “‘Going Green’ May Make You ‘See Red,’” Firehouse, June 2008.

- www.sprayfoam.org/files/docs/2015/Presentations/2E%20Advanced%20Best%20Practices%20for%20Avoiding%20Problems.pdf

- https://www.lapolla.com/wp-content/uploads/2013/10/072119-072129-lapolla-spray-polyurethane-foam-insulation-residential-envelope.pdf

- “Complete wall system including ½” particle board siding, 1/8” pressed cardboard sheathing and ½” gypsum board. http://www.oklahomafoam.com/foam_insulation_faq.htm; Johns Manville, “Sound Control Frequently Asked Questions,” January 2003”

- Johns Manville Spider® Acoustical Performance Advantages www.jm.com/content/dam/jm/global/en/buildinginsulation/Files/BI%20Toolbox/JMSpider_BID0080.pdf

- gpinsulation.com/products.htm

- www.insulation.org/io/article.cfm?id=IO120404

- Consumer Product Safety Commission Memorandum – September 22, 1983 – Summary of the Formaldehyde in Products Project

- NAIMA Publication N040 “Health and Safety Facts for Fiberglass”

- Richard T. Bynum, Jr., Insulation Handbook, New York: McGraw-Hill, 2001

- Thermal Barriers for the Spray Foam Industry, SPFA (2000)

- www2.buildinggreen.com/article/flame-retardants-under-fire

- www.gpo.gov/fdsys/pkg/CFR-2009-title16-vol2/pdf/CFR-2009-title16-vol2-sec1404-4.pdf